Hydroponic Plastic Components

There are several benefits to adopting hydroponics – a technique for growing plants without soil. It predominantly uses less water than conventional gardening practices as they do not have to be manually watered to replenish moisture. In addition, less waste is associated when growing plants hydroponically as no soil is wasted when beginning fresh with new plants.

At Vicplas, we believe in effective techniques for growing plants. Whether you are looking to complete a hydroponic system for an indoor or outdoor set-up, a simple gardening kit, or farming products – Vicplas offers a wide selection of hydroponic plastic components customised to the hydroponic system.

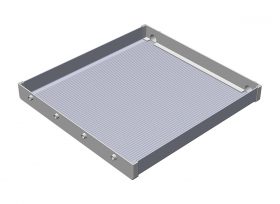

To best serve our local and regional customers, our extensive selection of quality uPVC pipes and fittings, channels/gutters, and trays are sustainable and safe in all agricultural environments.

Heavy Metals Free uPVC Piping Products

Our heavy metals free and environmentally friendly uPVC piping products are part of our core values to forge a more sustainable and greener future. We pride ourselves upon our heavy-metals-free and non-toxic channels, which make our piping systems suitable for long-term operational use when it comes to operational hydro-agriculture in Singapore.

Designed with an extended lifespan and minimal maintenance, they are built to last, and we adopt a zero-waste management strategy where the polymers we use are fully recyclable.

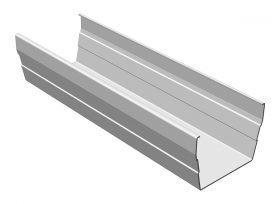

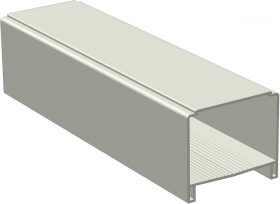

Our VPONIC™ series of channels has been developed to promote high-yield farming with its excellent flow properties and weathering resistance. Each channel or gutter in our plastic components has enhanced properties to allow for the free flow of water while reducing ultraviolet rays and promoting oxygenation. Our hydroponic farming products are further designed to consume less water, allowing our customers to maximise their resources and reduce cultivation costs, making it the best solution for mobile and static hydroponic systems.

Research and Development

Our experts and professionals at the VPONIC™ Research and Development Centre strive for excellence in providing continual product improvements and new designs to meet market needs. To fulfil our commitments, we are constantly raising our bar and reassessing our solutions and products with these questions on sustainability:

- Are our plastic components ethically produced and friendly to the environment?

- Are they cost-efficient enough to meet the demands of consumers?

- Are they built and designed for long-term use with minimal maintenance?

- Are they guided by the principles of the three Rs – Reduce, Reuse and Recycle?

- Are they aiding in efforts to minimise waste?

In addition to supporting research and development in product advancements, Vicplas contributes to the Singapore Government’s ‘30 by 30’ plan by manufacturing the plastic components for hydroponic systems that is beneficial in hydroponics farming.

In hydroponics, the soil is replaced with a nutrient-rich solution that is continuously pumped through water pipes and drip emitters. The system is designed to deliver optimum levels of water, nutrients, and sunlight to the plants. In order to accomplish this, the pipes need to be manufactured from a material that will not corrode or rust in the presence of these chemicals.

Vicplas invests in R&D activities for innovation and technological advancement in plastics for hydroponic systems to meet the future needs of the hydroponic farming sector and its stakeholders. We manufacture products that are sustainable and economically viable for farmers, supporting them in building our nation’s agri-food sector to develop its potential to meet 30% of our country’s nutritional needs locally and sustainably by 2030.

Capabilities and Certifications

If you are looking to buy components to complete your hydroponic system in Singapore, Vicplas is your one-stop centre with our custom designs and fabrications for channels, gutters, trays and other uPVC profiles – all tailored to suit your individual needs. Here’s what you can expect when shopping with Vicplas:

- Product Design: We develop practical solutions aligning with the market’s changing needs and help you get the most out of your purchases.

- Processing Techniques: Our proficiency across a wide range of polymer processing techniques allows us to offer all kinds of processes, including injection, extrusion, thermal forming, and fabrication.

- Tool Fabrication: We offer custom fabrication, implementing innovative and out-of-the-box designs to develop creative solutions for various requirements.

- Material Science: Our extensive working knowledge of polymeric materials such as engineering plastics, speciality elastomers, and more puts us in the best position to offer you the solutions you need today.

Our products are also ISO 50001, ISO 45001, and ISO 14001 certified. We have a company-wide focus on the importance of sustainability and believe that the drive towards transparency will lead to greater adoption of our products. With its increasing focus, we believe that our products can play a greater role in helping people. Those looking to buy environmentally sustainable goods can benefit from our products.

SGBC-BCA Award in Sustainability

Vicplas has recently received SGBC-Business BCA’s Leadership Award in Sustainability. Being given the corporate leadership in Sustainability – Innovation award has surprised and honoured us. It is an acknowledgement of our efforts to promote sustainability and green practices. As we advance, sustainability has become fundamental to our operations as we work to make substantial differences in society. This motivates us to keep moving forward on our quest to embrace novel possibilities through environmentally friendly fixes.